TorqueStitch Installation Guide

Follow these steps for a successful installation of TorqueStitch Mechanical Stitches:

- Locating the Stitch:

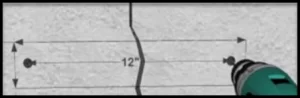

- Trace a rectangle measuring 13” x 1-1/2” on the concrete surface. Mark two holes 12” apart as indicated in the diagram.

- Drilling Holes:

- Use a 1/2” masonry bit to drill both marked holes into the concrete to a depth of approximately 4 inches.

Cut and Chip rectangular area.

- Use a 1/2” masonry bit to drill both marked holes into the concrete to a depth of approximately 4 inches.

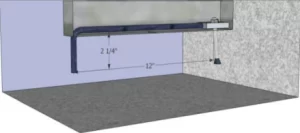

- Creating the Box Niche:

- Cut and chip a rectangular area approximately 1-1/2″ deep using a masonry saw and chipping hammer. For cleaner cuts, pre-slice the rectangular area with the saw before chipping. Clean out all debris thoroughly. Expand one hole with a 5/8” drill, ensuring the holes are 2 1/4” deep below the niche bottom. Avoid over drilling.

- Anchor and Stitch Placement:

- Place the sleeve anchor through the bottom of the stitch. Thread the nut onto the top of the shaft for 3-4 turns, ensuring the end marked XXX is at the bottom of the anchor. Insert the sleeve anchor into the 5/8” hole, hook into the 1/2” hole, and gently tap the nut’s head until the sleeve is fully inserted and flush with the niche bottom.

- Securing the Stitch:

Insert stitch and tighten. - With a ratchet and a 3/4″ socket, tighten the nut on the anchor for about 3-4 turns up to 50 Ft-Lb torque. Be meticulous in placing each stitch, as the Mechanical Stitch installation is meant to be permanent. Once installed and tightened, the anchor is not designed to be removed or relocated.

- Repeating the Procedure:

- Repeat the procedure for each stitch, spacing them approximately 1 foot apart along the crack (typically 10 Mechanical Stitches for a 10-foot crack).

- Completing the Repair:

- For a comprehensive repair, fill the niche with epoxy or urethane mortar, ideally suited for areas subject to chemical spills, heavy equipment, and continuous traffic.

Additional Notes:

- Slab Thickness: A minimum slab thickness of 5 inches is recommended for Mechanical Stitch installation. For thinner slabs, drill the anchor hole, install, and tighten the nut. If the threaded shaft extends upward post-tightening, it can be ground down flush with the nut. Ensure the niche bottom is as flat as possible for optimal installation performance.

This guide provides a step-by-step approach to installing the TorqueStitch Mechanical Stitches, ensuring a durable and effective repair for concrete cracks.